Reducing vehicle criteria and greenhouse gas emissions

By George Survant and Christopher Lyon

A common definition of sustainability is reducing harm on the environment. In fleet terms, it typically refers to moving your fuel type to renewable sources and reducing your criteria and greenhouse gas emissions profile. Consequently, most fleet operators strive for a balance of both approaches, depending on their fleet mission and available alternatives that meet their specific needs.

According to Energy Information Administration (EIA), renewable energy comes from sources that are naturally replenishing but flow-limited. They are virtually inexhaustible in duration but limited in the amount of energy available per unit of time.

EIA outlines the major types of renewable energy sources.

Biomass includes

o Wood and wood waste

o Municipal solid waste

o Landfill gas and biogas

o Ethanol

o Biodiesel

Hydropower

Geothermal

Wind

Solar

While it may not be obvious that all of these fuel types are suitable for transportation, all biomass fuels do have a means to convert to liquid or gaseous fuels (renewable CNG, for example), and there are success stories of fleets running on landfill gas. In the Netherlands, biomass “digesters” are in continuous use as a renewable fuel source. Remaining sources all create electricity, which is growing in popularity as a transportation fuel.

There are significant challenges for fleets transitioning to effective sustainability solutions. Typically, the central significant issues revolve around fleet replacement planning and how to address a legacy fleet. Each of these issues can have different solutions while focusing on the same outcome — improved sustainability.

Replacement vehicle challenges revolve around selecting the best fit for your application among the alternatives. On the other hand, dealing with improvements to your legacy fleet represents a very different problem. Many of the best technologies are expensive and difficult to retrofit, even when possible. In some cases, a retrofit investment will meet or exceed the vehicle’s value at its current age.

The choice challenge is difficult simply as a result of the wide variety of available products. There’s fascinating growth in the number of products fueled by electric energy, such as battery electric, hybrid electric, plug-in hybrid electric and fuel cell vehicles. Beyond electric solutions, CNG, propane and LNG also offer reduced engine emissions as compared to traditional petroleum options. In addition to changing engine technologies, viable solutions for meeting your sustainability goals should include renewable fuels. Renewable CNG, renewable diesel, ethanol and biodiesel fuels represent an excellent retrofit strategy for most fleets.

Know the options

By understanding your options and planning thoughtfully, you can map your future acquisitions with a focus on reduced emissions and/or renewable fuel products. Many specialized vocational trucks are extremely complex and expensive, with a longer life cycle than standard or off-the-lot vehicles. This will, in most cases, require some acquisition/support infrastructure like specialized refueling stations or, for electric options, recharging infrastructure. While there are many alternative fuel and technology choices, they all require some degree of infrastructure.

Infrastructure can be a challenge on its own, whether it’s the cost to install your own refueling site, using local public access stations, or in some cases, product availability. For example, a predominately warm region may not have the same gas pipelines installed for CNG as colder locations (a result of using the same fuel for home heating). Although building a sustainable legacy fleet may not draw as much attention as the latest emerging technologies, it can positively influence the budget as these solutions can sharply reduce the cost to move your fleet to improved sustainability. Sustainability can be as simple as doing the same amount of work while consuming fewer resources.

Monitor driver behavior

It is important to know how your fuel is being used to ensure the best fit for any fleet application. There are several identifiable drive patterns and cycles, but the most common four include

Highway operations — high mileage, high speed

Inner city urban operations — low mileage, low speed

Stop and go — pickup and delivery operations

Work support — high idle with power export (power takeoff operation, for example)

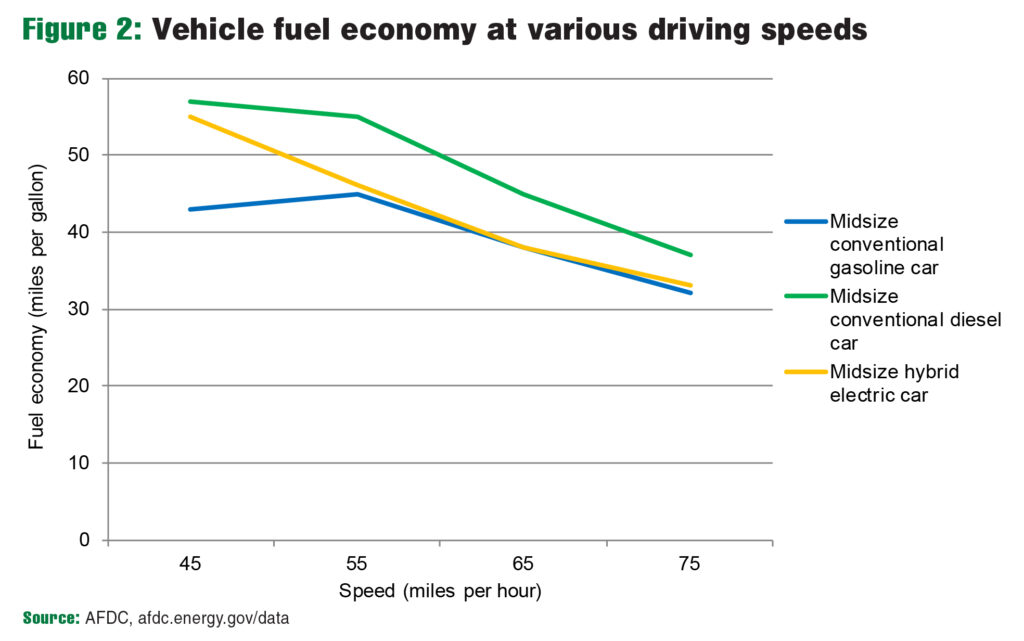

In addition, look carefully at your need for driver training. Hard acceleration and high-speed operations burn excessive amounts of fuel regardless of vehicle category. Driver behavior can be addressed through accurate monitoring and focused training. This will reduce excessive fuel use based on driving styles. Normalizing driver behavior can provide a consistent reduction in fuel use. Fuel reduction equates to consuming less energy, thus improving the sustainability of a legacy fleet.

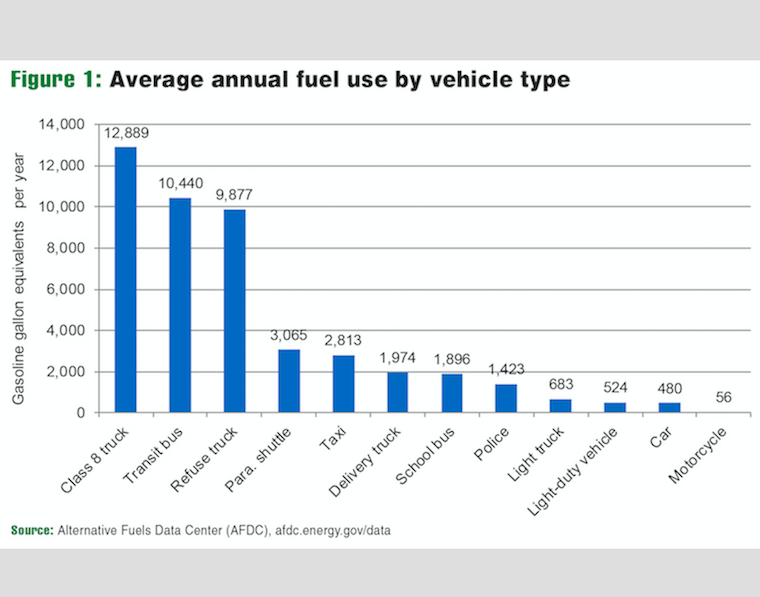

Vocational trucks account for significant fuel consumption. Educating operators on the influence vehicle speed has on fuel economy may be enough to change their behavior. Coupling education with consistent feedback on how the individual driver performs relative to peers can also spur improvement.

Financial impact

Evolving to sustainability is not an inexpensive task. It would be much easier if financial resources were unlimited; however, this is typically not the case. Every solution has a financial implication, and the smartest fleet operators often blend a series of solutions to optimize sustainability improvements, while minimizing the financial impact.

Replacements

It’s important to examine your entire fleet. Take time to complete a thorough life cycle cost analysis and understand what it means. One of the most common mistakes is to stop an evaluation after looking at the purchase price; often, a sustainable vehicle will have significantly lower lifetime fuel costs. Some alternatives have proven to provide much lower maintenance costs over the vehicle life.

Many fleet operations have a defined payback period to measure effective equipment deployment. Remember, when looking at a longer payback period while performing due diligence on your vehicle decision, there is no commonly accepted monetized value for sustainability. Consequently, when presenting recommendations to decision-makers, be sure to point out exactly how much greenhouse gas and criteria emissions will be reduced over the vehicle’s effective life. It’s important to account for maintenance savings and carefully research product resale value. All too often, when assessing resale value, decision-makers will use prevailing beliefs over facts.

Retrofits

Sometimes, retrofits are a great solution to improving sustainability. While not all technologies are appropriate for retrofits, some are well suited for improving legacy fleet sustainability performance. Liquid fuel substitutes (like biodiesel and renewable diesel) are great examples of retrofit strategies that are quick and inexpensive to deploy with well-documented performance improvements.

Retrofits require additional thought to ensure no unintended consequences. To the degree possible, it’s important to find drivers supportive of your sustainability goals. Uncooperative drivers can undermine the effectiveness of your program even if the side effect is only underutilized vehicles. It is essential, however, for fleet planners to take driver feedback very seriously when it comes to retrofit vehicle issues.

Looking ahead

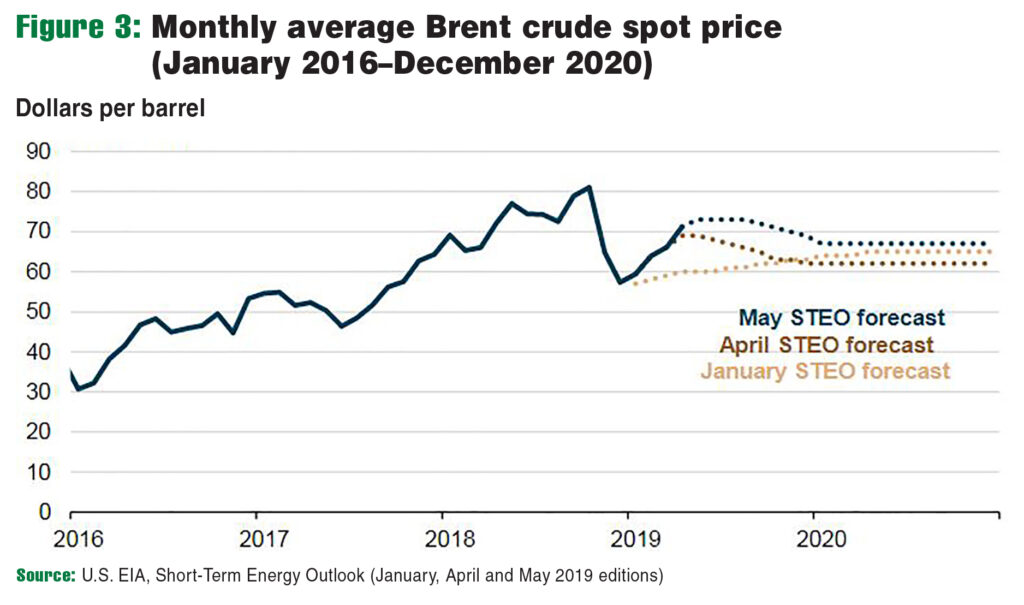

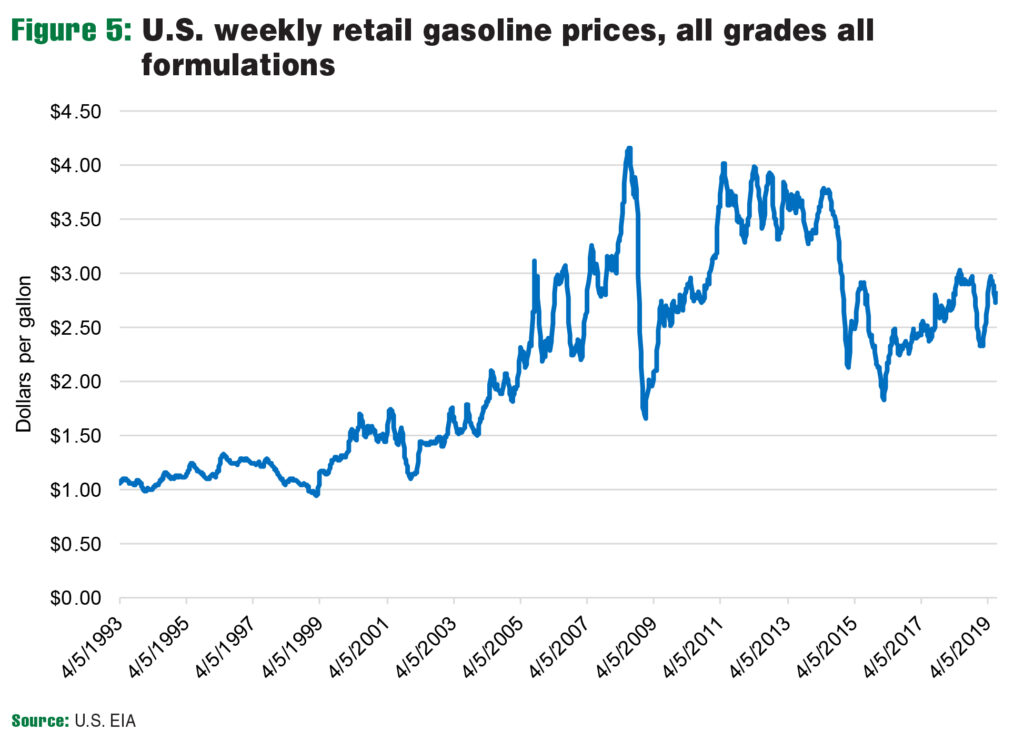

While price volatility of conventional fuel is the new normal, EIA’s forecast continues to indicate an upward spiral.

In 2008, when prices were at record levels, fleets that had adopted alternative fuels (such as CNG and propane autogas) were being hailed as money savers and environmental stewards — a definitive win-win for the fleet community. As markets cooled off and fuel prices stabilized a year later, so did the alternative fuel buzz. This has become a cyclical event. When prices rise, the appeal of alternative fuel options and technology increases. As prices drop, interest and action fall to the sidelines. Many fleets that have not yet adopted an alternative fuel position find themselves in a holding pattern. This represents missed opportunity for those waiting to discover the perfect solution.

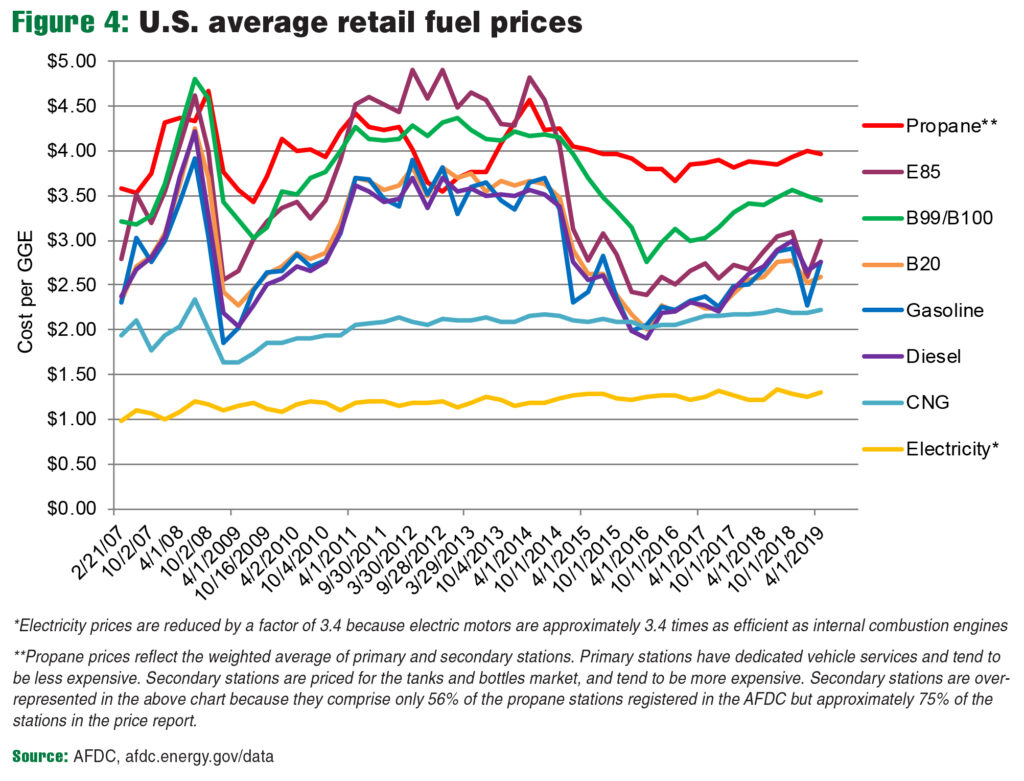

Price stability

One benefit of some alternative fuel and energy options (such as CNG and electricity) is proven price stability. While there is no way of knowing the future, historical data trends in favor of consistent energy costs.

CNG and electric costs have not been subject to large market fluctuations, which can allow for longer-term, more accurate life cycle cost projections.

What’s best for my fleet?

There is no single answer, and there are a lot of variables. It’s imperative to define the objectives and barriers of an organization before taking action. Considerations include

- Fuel costs

- Total cost of ownership

- Public image

- Continuity of fuel supply

- Regulatory compliance

Other factors include required capital investment, desired return on investment, vehicle and technology availability, and fuel access in a given geographic area.

Alternative fuels and electrification can deliver huge success reducing emissions and publicizing sustainable efforts. While there are wide differences in alternative fuel applications, it is important to understand the benefits of each.

- Biodiesel and renewable diesel, essentially a drop-in fuel requiring no modification to diesel vehicles

- Propane, relatively inexpensive infrastructure

- Compressed natural gas, inexpensive fuel source

- Plug-in hybrid and electric, inexpensive energy source

While these options all have benefits, there are some challenges. Some alternative fuels require complex fuel tanks that may interfere with previously designed vehicle functionality. Electric propulsion range is defined by available onboard energy storage (battery size); more/bigger batteries add weight, sometimes at the cost of payload. It is crucial to understand drive and duty cycle to best match the technology to the application.

Funding

Being sustainable and funding the mission can be difficult. When making the case for sustainability, there can be a twofold approach. First, there are long-term considerations. Many times, alternative technologies come with a larger upfront acquisition cost than conventional counterparts. Looking at long-term scenarios (such as conducting a life cycle cost analysis) is a critical step when making any decision.

Although a comprehensive life cycle cost analysis can be a time-consuming task, NTEA offers a Vehicle Life Cycle Cost Tool as a free member benefit (member login required). This cloud-based resource, designed to be flexible and user-friendly to accommodate a variety of truck life cycle analysis needs and different fleet structures, can aid the decision-making process. Learn more at ntea.com/lifecycle.

Second, federal and state funding can be vital. Lowering the final price for alternative and sustainable technology should be the priority for decision-makers. Running a life cycle cost analysis can reveal even further savings. Availability of state and federal funding can be in continuous flux. Having tools and resources at your disposal to research opportunities is crucial for long-term sustainability programs. Several supporting resources are available, including AFDC which houses a list of laws and incentives on both federal and state levels. Current incentives are outlined at afdc.energy.gov/laws.

Clean Cities coalitions, part of the Department of Energy’s Vehicle Technologies Office, foster the nation’s economic, environmental and energy security by working locally to advance affordable domestic transportation fuels, energy-efficient mobility systems, and other fuel-saving technologies and practices. There are nearly 100 local and regional coalitions serving as a resource for success stories, in addition to local and regional funding initiatives. Find details at cleancities.energy.gov.

CALSTART is a nonprofit organization working with businesses and governments on an international scale to develop clean, efficient transportation solutions. It’s a network that links companies and government agencies, connecting every element of the clean energy sector and helping them make enhancements. Access more information at calstart.org.

The cost of waiting

While adopting sustainability may seem challenging and expensive, there is a cost of waiting. New model vehicles increase in expense, and infrastructure costs have also risen historically. Key variables are fuel and maintenance costs and end-of-life resale value.

Fleet leaders should seek to enhance their fleet value equation, positioning them to access stable energy markets that provide long-term fiscal success.

Learn more

Green Truck Association (GTA), an NTEA affiliate division, offers a variety of resources to educate its members on techniques and technology that can improve fleet efficiency, reduce emissions across time, and lower the risk of fuel price volatility driving up operating expenses. GTA fleet members can get involved in a data logger drive and duty cycle program that provides information on how vehicles operate in varying environments; find details at greentruckassociation.com.

#

George Survant is senior director of fleet relations at NTEA, and Christopher Lyon is director of fleet relations at NTEA.Established in 1964, NTEA – The Association for the Work Truck Industry represents more than 2,100 companies that manufacture, distribute, install, sell and repair commercial trucks, truck bodies, truck equipment, trailers and accessories. Buyers of work trucks and the major commercial truck chassis manufacturers also belong to the Association. NTEA provides in-depth technical information, education, and member programs and services, and produces The Work Truck Show®. The Association maintains its administrative headquarters in suburban Detroit and government relations offices in Washington, D.C., and Ottawa, Ontario.